Dairy fermentation is one of the most ancient and widely practiced techniques in food production, with roots tracing back thousands of years. From the creamy textures of yoghurt to the rich flavours of cheese, fermented dairy products are a staple in diets across the globe. While traditional methods of fermentation relied on naturally occurring microorganisms, modern advancements in biotechnology have revolutionised the process, with enzymes taking centre stage. Cutting-edge enzymes are now indispensable in enhancing the efficiency, quality, and sustainability of dairy fermentation processes, paving the way for innovations in the dairy industry.

Enzymes are biological catalysts that speed up chemical reactions without being consumed in the process. In dairy fermentation, they play a pivotal role in breaking down complex molecules, transforming milk into a wide array of fermented products. Enzymes are particularly valued for their ability to ensure consistency and improve the sensory properties of the final product.

Traditionally, fermentation depended solely on the natural action of lactic acid bacteria. While effective, this approach often resulted in variable outcomes due to fluctuations in environmental conditions and microbial activity. By introducing specific enzymes, dairy producers can achieve greater control over the fermentation process, leading to consistent and high-quality products.

Key Enzymes in Dairy Fermentation

The advancements in enzymology have led to the development of a wide range of enzymes tailored specifically for dairy applications. Among these, the following enzymes are particularly noteworthy:

1. Lactase

Lactase, also known as β-galactosidase, is one of the most commonly used enzymes in dairy fermentation. Its primary function is to hydrolyse lactose—the natural sugar found in milk—into glucose and galactose. This enzymatic reaction is especially beneficial for producing lactose-free dairy products, catering to the growing population of lactose-intolerant consumers worldwide.

Moreover, lactase enhances the sweetness of dairy products without the need for added sugars, as the breakdown products of lactose are naturally sweeter. This makes lactase an invaluable tool for creating healthier dairy alternatives.

2. Proteases

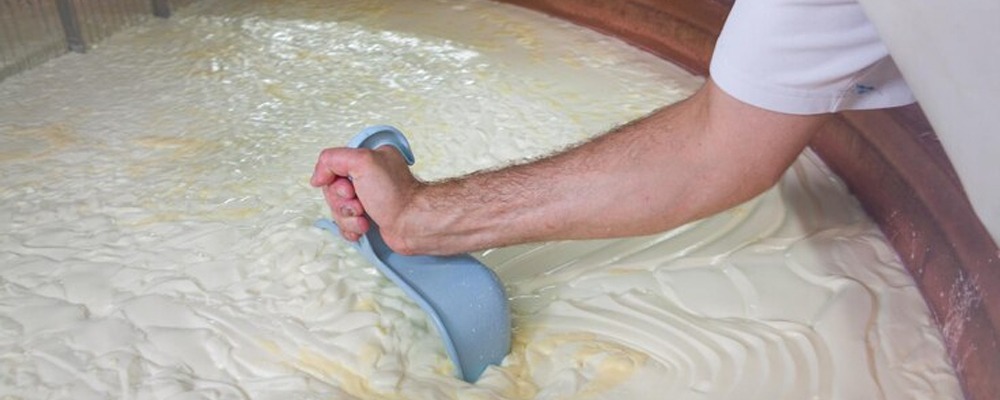

Proteases are enzymes that break down proteins into smaller peptides and amino acids. In dairy fermentation, proteases play a crucial role in the production of cheese. By breaking down casein, the primary milk protein, proteases facilitate the coagulation of milk, forming the curds essential for cheese-making.

Beyond coagulation, proteases contribute to the development of flavour and texture in aged cheeses. The enzymatic breakdown of proteins releases peptides and amino acids that serve as precursors for the complex flavours associated with mature cheeses. Advances in protease technology have enabled dairy producers to tailor enzyme formulations to achieve specific flavour profiles and textures.

3. Lipases

Lipases are enzymes that catalyse the breakdown of fats into glycerol and free fatty acids. While their role in dairy fermentation is less prominent than that of lactase or proteases, lipases are essential for developing the characteristic flavours of certain cheeses, such as blue cheese and Parmesan. The enzymatic release of free fatty acids contributes to the pungent and nutty notes that define these products.

Modern lipase formulations are highly specialised, allowing dairy producers to control the intensity and type of flavour development. This precision has opened up new possibilities for creating innovative cheese varieties.

4. Transglutaminase

Transglutaminase, often referred to as the “glue enzyme,” is gaining popularity in dairy fermentation for its ability to modify protein structures. By catalysing the formation of covalent bonds between proteins, transglutaminase enhances the texture and creaminess of dairy products such as yoghurt and cheese. It is particularly useful for improving the structural integrity of low-fat or plant-based dairy alternatives.

This enzyme also has applications in reducing whey protein waste, as it enables the incorporation of whey proteins into dairy products, thereby improving overall yield and sustainability.

5. Amylases

Amylases, which break down starch into simpler sugars, are not traditionally associated with dairy fermentation. However, their inclusion in certain processes, such as the production of flavoured yoghurts and dairy-based desserts, has proven beneficial. By converting residual starches into fermentable sugars, amylases enhance the sweetness and overall sensory profile of these products.

The Benefits of Enzymes

The integration of cutting-edge enzymes into dairy fermentation offers numerous advantages that extend beyond improved efficiency and product quality:

- Enhanced Sustainability: Enzymes reduce waste and energy consumption by streamlining fermentation processes. For instance, proteases and transglutaminase minimise protein waste, while lactase enables the utilisation of whey, a by-product of cheese-making, in other applications.

- Improved Digestibility: Enzymes such as lactase and proteases enhance the digestibility of dairy products, making them suitable for consumers with dietary restrictions or sensitivities.

- Customisation: Modern enzyme formulations can be tailored to achieve specific characteristics in dairy products, from unique flavour profiles to desired textures, catering to diverse consumer preferences.

- Cost-Effectiveness: By optimising fermentation processes, enzymes reduce production costs, enabling dairy producers to maintain competitive pricing while delivering high-quality products.

Challenges in Enzyme Application

Despite their numerous benefits, the application of enzymes in dairy fermentation is not without challenges. The cost of enzyme production remains a significant barrier, particularly for small-scale producers. Additionally, the specificity of enzymes means that careful optimisation is required to achieve the desired outcomes, necessitating specialised knowledge and equipment.

Another challenge lies in consumer perception. While enzymes are natural and safe, some consumers may associate them with overly processed foods. Transparent labelling and education about the benefits of enzymes can help address these misconceptions.

The Future of Enzymes in Dairy Fermentation

The future of dairy fermentation is inextricably linked to advancements in enzymology. Innovations in genetic engineering and synthetic biology are enabling the development of enzymes with enhanced stability, activity, and specificity. For instance, engineered lactases that remain active at higher temperatures are making lactose-free dairy production more efficient.

Moreover, the integration of digital technologies, such as artificial intelligence and machine learning, is facilitating the optimisation of enzyme applications. These tools enable dairy producers to model and predict enzymatic reactions, ensuring consistent and high-quality results.

Biolaxi Enzymes: Empowering the Dairy Industry

At Biolaxi Enzymes, we recognise the transformative potential of enzymes in dairy fermentation. With years of expertise in enzyme formulations, we are committed to providing cutting-edge solutions tailored to the unique needs of the dairy industry. Our portfolio includes a diverse range of high-quality enzymes designed to enhance the efficiency, quality, and sustainability of dairy production.

Whether you’re looking to create lactose-free products, develop unique cheese varieties, or improve the texture of your yoghurts, Biolaxi Enzymes has the expertise and products to help you achieve your goals. Partner with us to harness the power of enzymatic innovation and take your dairy fermentation processes to the next level. Together, we can shape a more sustainable and flavourful future for the dairy industry.